Creating a Perfect System

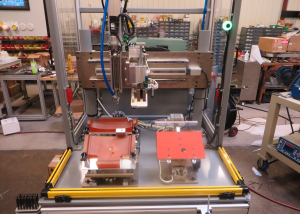

Creating systems ultimately depends on the necessary assemblies to be included. At Craig Machinery, we will tackle just about any assembly type as our experience is vast. We have constructed machines that spring load, press, fasten, cut, bend or fold materials into place. Some systems are fully automatic while others are manual workstations. The application depends on the process which products is assembled.

Often, clients want a system that does more than just assembly. Add additional applications in one machine helps speeds up the process, makes it more cost effective and conserves space. It is common to include laser marking, welding, cutting, dispensing, leak testing and other stations in a project. We understand incorporating transportation between stations help streamline the process and lessen the workload of the operator. These mechanisms can include rotary systems, pick & place, robots, or coyer belts.

For more on our inhouse capabilities, click here.