Clamshell Blister Packaging

Since presentation is everything, it is no surprise that clamshell blister packaging is on the rise. These clear cases provide high visibility to the consumer. The packaging contains no adhesives, heatshrink bands or staples leaving the final product with an attractive appearance. Clamshell blister packaging are perfect for the food and beverage industry for its tamper-resistant design, and Craig Machinery pioneered the machines for that type of packaging. A few years ago, we teamed up with a lettuce producer to create a packing machine. We created an application that includes high speed lettuce tub lid welders with speeds of up to 100 fpm. Now, clamshell blister packaging is the norm for the produce and baking industries.

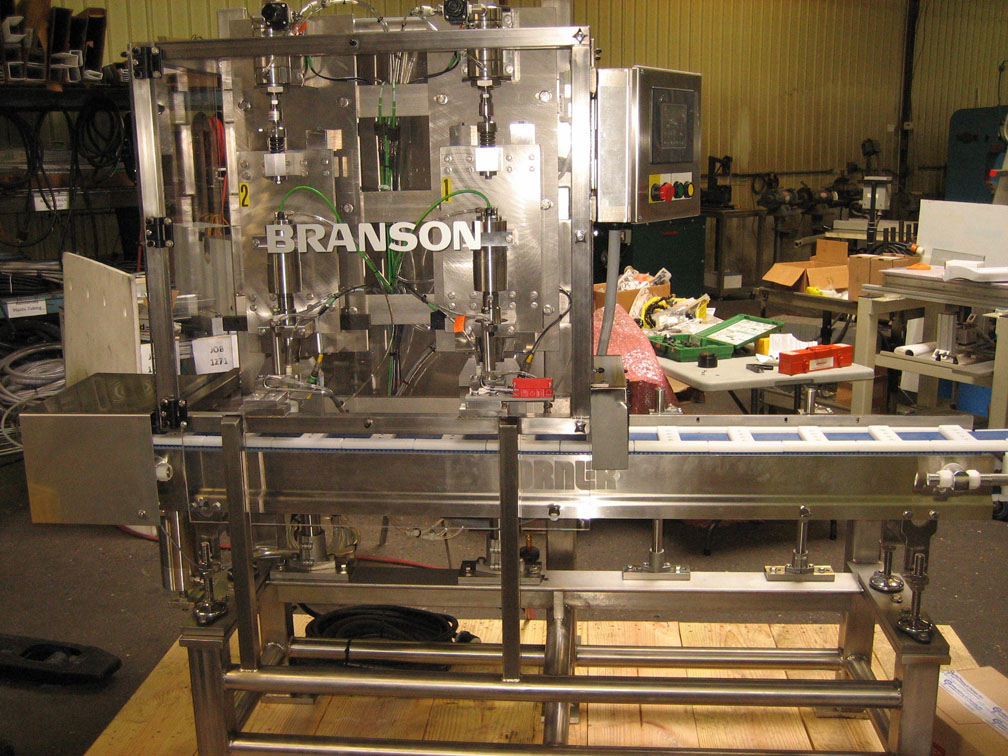

We have experience working with polyethylene terephthalate (PET), recycled polyethylene terephthalate (RPET), and polyvinyl chloride (PVC) materials. We can also build machines for plunge welding clamshell packages for a variety of sizes and cycle times. Craig Machinery can build machinery for almost any need, from “simple load under the horn” table systems with two palm buttons to multi-welder rotary indexing machines with an auto eject system and an operator interface touch screen.